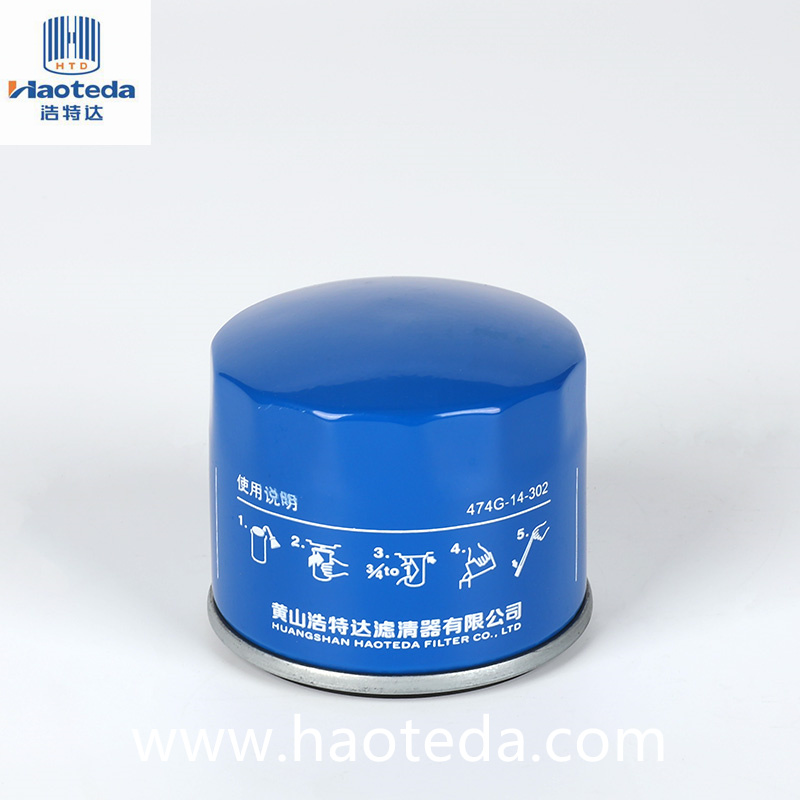

Metal oil filters play a pivotal role in maintaining engine health by ensuring that the oil circulating through an engine is free of contaminants. These filters are robust and durable, typically constructed with a metal canister that houses the filtration media, a critical component responsible for trapping impurities. The exterior of the filter, made of metal, offers protection against harsh environmental conditions and mechanical stress. The base plate of the filter, which includes a sealing gasket, ensures a tight fit against the engine's mating surface, preventing oil leaks and maintaining the system's integrity. This plate is perforated with holes that facilitate the flow of oil through the filter, allowing it to be cleaned before re-entering the engine's lubrication system.

The performance of metal oil filters largely depends on the type of filtration media used. Various filtration media can be employed, each with unique characteristics and advantages. The most common types include cellulose, synthetic, and blended media. Cellulose media, made from wood pulp fibers, are often used in standard oil filters. They are effective at capturing larger particles, typically down to 20-40 microns in size. However, cellulose filters may have a shorter lifespan and lower overall efficiency compared to other media types.

In contrast, synthetic media, composed of man-made fibers such as glass or polyester, offer superior performance. These fibers are more uniform in size and shape, allowing for more consistent filtration. Synthetic media can capture smaller particles, down to 5-20 microns, which provides better protection for the engine. Additionally, synthetic filters generally have a longer service life due to their higher capacity to hold contaminants. They also maintain their efficiency over a broader range of temperatures, making them ideal for high-performance and severe driving conditions.

Blended media, as the name suggests, combine cellulose and synthetic fibers, aiming to balance cost and performance. These filters can provide better filtration than pure cellulose media while being more affordable than fully synthetic options. They offer a middle ground, with decent efficiency and capacity to hold contaminants, suitable for a wide range of vehicles and driving conditions.

The choice of filtration media significantly impacts the effectiveness of metal oil filters. For instance, vehicles that are used in extreme conditions or those that require high performance will benefit more from synthetic media due to its superior filtration capabilities and durability. On the other hand, for everyday driving under normal conditions, cellulose or blended media can be sufficient and more cost-effective.

Our Metal oil filters exemplifies the advantages of advanced filtration technology. It incorporates high-quality synthetic media that provides exceptional filtration efficiency and a longer service life. This ensures that your engine remains protected from harmful contaminants, reducing wear and tear and extending its lifespan. The robust metal canister and precision-engineered sealing gasket further enhance the reliability and performance of our filters, making them a superior choice for discerning vehicle owners.

Understanding the differences in filtration media is crucial for making an informed decision about oil filter selection. By choosing a metal oil filter with the appropriate media for your vehicle’s needs, you can ensure optimal engine protection and performance. Our Metal Oil Filter, with its superior synthetic media and durable construction, represents the pinnacle of oil filtration technology, delivering unmatched reliability and protection for your engine.

English

English

English

English Español

Español Français

Français

+86-139-6774-0263

+86-139-6774-0263